- Products features

-

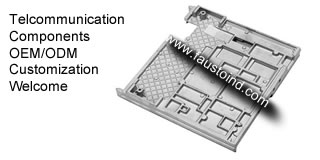

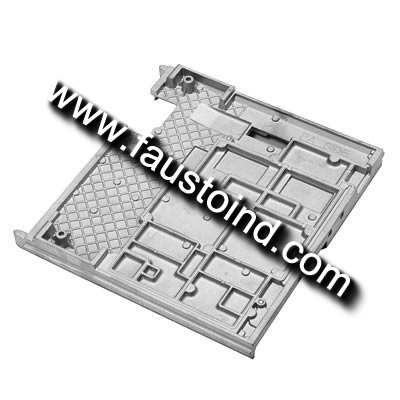

aluminum die casting Telecommunications componentsKey Specifications/Special Features:

- Zinc alloy: Zamak 3#, Zamak5#

- Other raw materials are available

- Aluminum alloy: A380, ADC12, other raw materials are available

- Surface treatment: debarring, polishing, sandblast, grind, spray coating, oxygenation, electroplating and more

- Drawings or samples are all acceptable

- Lead time for die tooling and sample: 20 to 35 days

- Software for specification drawings: auto CAD, pro engineer, UGS NX

1.15-year experiences

2.Material:aluminum

3.Process: die casting

3.Drawings are welcome1. Ability

1 material grey iron, ductile iron, steel, stainless steel, brass, copper, bronze, aluminum, zinc etc

2 process sand casting, precision casting, lost wax casting, die casting, forging, stamping, machining etc

3 machine lathe, CNC, drilling machine, milling machine, boring machine, planting machine, machining center

4 tolerance casting:0.5mm, machining:0.05mm, finish machining:0.005mm

5 capacity max diameter:1M, max weight:200KG

6 surface treatment powder coating, painting, spraying, galvanization

7 standard JIS, ANSI, DIN, BS, GB

2.OEM and Customized Service

1.Quality guaranteeChemical checking

NDE after rough machining

Machanical testing after heat treatment

Final NDE,dimension inspected

2.Quality document

- Full Q.A document as per client request

3.Packing and Shipping

- standard export package(carton/wooden case/pallet)

- accept FOB,FAS,CNF,CIF door to door etc or customer designated shipping agent

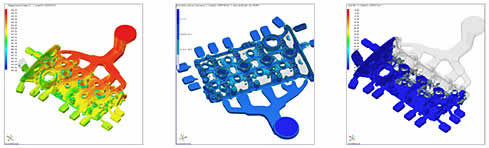

R&D

Being a High –tech enterprise .Fausto Industry is mainly specialized in designing ,developing and Manufacturing large scale ,precision and complex die casting mould with strong R& D capability .

Fausto Industry has more than 30 designers ,engineers and technicians ,Which accounts for 28% of Company personnel .

Fausto Industry have very strong R& D ability and has successively developed a batch of difficult and advanced level die casting mould .That including : V 6 Engine Block V4 engine Block .Auto-transmission .Redirector Bracket . Instrument Panel .Valve body ect.

Fausto Industry Took the lead in introducing the Flow simulation ---ADSTEFAN from Japan in 2003 ,and also the original design software ,Like PRO/E, Solidworks,UG, ext.

Achieved All 2D and 3D drawing ,The mould manufacturing according to design drawing .To ensure the mould repair and replacement of interchangeability .To provide a reliable guarantee for the mould Maintenance.

Quality management

Fausto Industry has very advanced inspection equipment.Such as : CMM.Metal Detector Metal metallographic analyzer ,Impact testing Machine .Al direct reading spectrometer .Tensile testerX –Ray detector.Hardness testing .To ensure the inspection from Incoming Material .Mould manufacturing to The T1 SamplingFausto Industry emphasized Quality management . Management criterion and passed ISO9001 quality certification.

- Photo

-